This guide helps manufacturers, packers, importers and sellers of pre-packaged goods understand their obligations under national trade measurement laws, particularly in relation to package labelling and accurate measurement.

Australia’s trade measurement laws regulate the measurement of pre-packaged goods by quantity.

Pre-packaged goods

Under national trade measurement legislation, manufacturers, packers, importers and sellers of pre-packaged goods must:

- ensure packages are correctly labelled; the laws include requirements for measurement marking and packer’s identification

- ensure packages they import, pack or sell include a measurement marking

- ensure the measurement marking is accurate and does not include the weight of any packaging material

- have appropriate measuring instruments: any measuring instruments used to perform compliance sampling must be suitable for the task, and properly maintained to ensure they remain accurate at all times

- assist trade measurement inspectors with any enquiries and provide information if required.

Pre-packaged goods with common measurements

Manufacturers, packers and importers, can choose either of two methods for determining the measurement of pre-packaged goods with common measurements or ‘constant nominal content’.

The first method is the average system where:

- the average content in a sample of pre-packaged goods of the same kind and measurement cannot be less than the stated quantity marked on the packages

- no package can have a shortfall greater than 5% of the stated quantity

- the permissible average deficiency in a sample of 12 or more packages is nil (see exceptions below) – an inspector will generally check 12 packages but can choose a number of packages greater than 12 for this sampling process, depending on the circumstances

- a small number of ‘desiccating’ goods (that is goods, such as mushrooms and soap, that lose moisture after packing) are allowed a greater permissible maximum deficiency and an average deficiency after the day of packing to reflect this moisture loss. You should check the detail of the trade measurement laws for these desiccating goods and the measurement-marking requirements.

The second method is the Average Quantity System (AQS). Under AQS, manufacturers, packers and importers, must comply with three important rules:

- the average net content in a sample from the production run of pre-packaged goods cannot be less than the stated quantity marked on the packages

- allowance is made for a small number of packages to exceed a ‘tolerable deficiency’

- none of the packages in the sample can have more than twice the prescribed tolerable deficiency.

Find out more about the Average Quantity System.

Pre-packaged goods with differing measurements

These goods are known as random-weight or catch-weight packages. It is not possible to undertake a sample because while they are the same kind of product, the measurement differs. It is not meaningful to calculate an ‘average’ measurement.

The measurement of any such package – whether it is expressed as weight, volume, number, area or length – must not be less than the measurement stated on the package label. The legislation does not allow for any deficiency in even a single package’s contents.

The legislation does not allow a deficiency for ‘desiccating’ goods, other than pre-packaged fresh mushrooms or pre-packaged soap marked “mass when packed”. If the product is likely to lose weight over time through evaporation, dehydration or other means, the packer must make allowances for any expected losses in the measurement when packaging the product for the entirety of its shelf life.

All goods pre-packaged for sale must be marked with the net measurement (i.e. the weight of the contents without the packaging material).

Unit price marking for retail sale

Many pre-packaged goods which are sold by weight (especially foods such as fruit, vegetables, cheese, meat, fish and smallgoods) are sold by unit price that is price per kilogram. These pre-packaged goods should be marked in the required manner with the weight, price per kilogram and total price for the article.

Sale by number or linear or area measurement

Certain products do not have to be sold by weights or volume when pre-packaged, but can be sold by number or linear or area measurement. You can find a list of these products at Approval for the sale of products by number or linear or area measurement.

Labelling requirements

There are a number of detailed requirements for labelling in the national trade measurement laws to make sure that the buyer is properly informed.

Position of the measurement marking

The marking that states the measurement of the package (weight, volume, length, area or number) must be on the main display part of the package. It must also be shown on at least one of the other parts of the package if it is likely to be displayed to the buyer. There is an exception from this requirement for bottles or casks of wine.

When the package is substantially cylindrical, spherical, oval or conical, the measurement marking must be wholly contained within a 60 degree arc either side of the line drawn vertically through the centre of the main display panel.

Size of the measurement marking

The minimum character size of the measurement marking on a package depends on the maximum dimension of the package (see Table 1):

- for rectangular packages the maximum dimension is the greater of the height, length or breadth of the package;

- for cylindrical, oval etc. packages the maximum dimension is the greater of the height, length or diameter of the package.

If the measurement marking is stamped or embossed instead of printed, the character size must be at least three times the minimum printed character size in Table 1. If you use an NMI-approved printing device for the measurement marking, the characters must be at least 3 mm high.

| Maximum dimension of package | Minimum character height of printed numbers/letters |

|---|---|

| 120 mm or less | 2 mm |

| Over 120 mm but not over 230 mm | 2.5 mm |

| Over 230 mm but not over 360 mm | 3.3 mm |

| over 360 mm | 4.8 mm |

Units of measurement and their symbols

The table below shows the units of measurement and the symbols allowed on measurement markings.

The degree of accuracy of a measurement marking, should not exceed three significant figures (unless the measurement marking is made by a printing device with NMI approval which allows for greater precision), e.g. 7.632 is not allowed; the correct measurement marking is 7.63.

Fractions of units must be shown as decimals and the decimal must be preceded by zero, or another numeral, e.g. ¼ kg must be shown as either 0.25 kg or 250 g.

| Measurement units allowed | Abbreviations allowed | Abbreviations NOT allowed |

|---|---|---|

| kilogram | kg | KG, Kg, kilos |

| gram | g (for any mass exceeding 1 000 g, use kg) | G, gm, grammes, grm |

| milligram | mg | MG, Mg, Mgram |

| Measurement units allowed | Abbreviations allowed | Abbreviations NOT allowed |

|---|---|---|

| litre | L (lower case l is permitted but is better to avoid) | None identified |

| decilitre | dL or dl | Dl |

| centilitre | cL or cl | Cl |

| millilitre | mL or ml (for volumes above 1000 millilitres use litre, decilitre or centilitre) | Ml |

| Measurement units allowed | Abbreviations allowed |

|---|---|

| cubic metre | m³ |

| cubic centimetre | cm³ (for any solid exceeding 1 000 cm³ use m³) |

| Measurement units allowed | Abbreviations allowed |

|---|---|

| metre | m |

| centimetre | cm (if length does not exceed 100 cm) |

| millimetre | mm (if length does not exceed 1 000 mm) |

For linear measurements, millimetre is also allowable:

- for paper lengths up to 10 000 mm, building material in sheet form and coated abrasive belts

- to express the linear measurement of an article if its use was customary before introduction of the National Trade Measurement Regulations 2009.

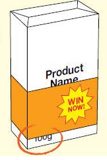

Common measurement marking mistakes

Incorrect

The product name is overlapping the measurement marking.

Correct

The measurement marking is clear to read, 2 mm from the edge of the package, with a clearance of 2 mm in all directions from other graphic material or text.

Incorrect

The measurement marking should be printed in the same direction as the brand name.

Correct

The measurement marking is clear to read and in the same direction as the brand name.

Incorrect

An additional strip (such as promotional competition items) should not hide the measurement marking.

Correct

The measurement marking and product name needs to be clear to read when any additional strip is added to the package.

Name and address of packer

For goods packed in Australia, the name and address of the packer (or the person on whose behalf it was packed) must be clearly marked on the package. The address must be a street address within Australia. Post office boxes, email and website addresses are not permitted as substitutes for street addresses.

Trade measurement laws do not prescribe the size or location of the name and address of the packer, but the details must be clear and legible.

For imported food (which includes beverages and ingredients) the Australia New Zealand Food Standards Code (the Code) requires that the name and business address in Australia of the importer or seller must be clearly marked on the package. The Code is a collection of Australian and New Zealand food standards with the force of law.

Packer, importer and sellers’ responsibilities

Packers, importers and sellers, have a responsibility to ensure their company’s operations have systems in place to achieve compliance with the national trade measurement laws. They need to:

- show that the goods they sell are labelled correctly and the quantities contained in the packages meet the measurement requirements

- take responsibility for the accuracy and marking of packages which they import, produce or sell and make sure that staff, systems and equipment, comply with the trade measurement laws

- ensure that authority is delegated to competent staff and there is proper and ongoing training of staff and appropriate supervision of processes.

Packers need to make sure that their staff are fully aware of the requirements of the national trade measurement laws and can demonstrate that internal quality control systems are in place.

Importers should insist that their suppliers are aware of the requirements of the national trade measurement laws and can demonstrate that they comply with the laws in terms of quality control systems. They should have a quality control system to monitor and verify compliance of imported goods before distribution and sale.

Sellers should insist that their suppliers – both packers and importers – are aware of the requirements of the national trade measurement laws and can demonstrate that they comply with the laws and have in place quality control systems. They should have in place their own quality control system to monitor and verify compliance of the goods they sell.

While the method of checking the measurement of packages and recording the results of process and compliance sampling is not prescribed by law, the more extensive the checks and records, the more packers/importers/sellers can prove that they did everything in their power to ensure the correct measurement of the packages. The extent of these checks depends on each set of circumstances.

Packers, importers and sellers should:

- demonstrate good operational practices in accordance with any appropriate recognised industry code which reflects trade measurement requirements

- ensure processes and procedures include a checking and auditing loop to demonstrate compliance with the trade measurement legislation

- make sure that researched and documented measurement records, with a history of past performance, are used to determine future fill settings

- determine the sampling frequency based on the understanding of processes and procedures and natural process variabilities; in a high-volume mass production operation, process sampling would generally be a separate action from compliance sampling whereas, for smaller operations it may be practicable to merge these two sampling activities into one function

- ensure work instructions and procedures include documentation such as training records, supervisory checks, measuring instrument checks and remedial actions and revised measurement targets.

What to do with shortfall packages

Sometimes compliance sampling might indicate that packages have a shortfall, i.e. the measurement of the package is less than that stated on the label. Remedial actions must be taken if:

- a single package deficiency exceeds the permissible tolerance and/or

- the average (or the weighted average in the context of AQS) measurements of sample packages is less than the nominal measurement marking.

In either case you will need to:

- identify the faulty packages

- remove them from your distribution channel, and place them in quarantine

- clearly mark the packages to prevent their inadvertent release

- report the details to senior management

- implement appropriate preventative measures.

Note: Even if non-compliant packages are sold at a substantial discount (or even given away) you still have to ensure that the correct measurement is marked on the package and that you comply with the trade measurement laws.

Identify the causes and take remedial action

- Review processes and procedures including the efficiency and accuracy of process sampling

- Identify and adjust any faulty equipment or process. If this is not possible, tag out equipment identified as faulty

- Consider operator retraining or closer supervision if that seems appropriate.

Re-labelling packages

- Re-labelling to a lesser marked measurement must be consistent with the trade measurement laws. However before re-labelling, consider whether this may cause marketing problems. Discuss this with your retailer. Buyers may expect a constant nominal quantity for particular-sized containers even though the laws may not require it

- A person who re-labels a package with a revised measurement marking is responsible for the accuracy of that measurement marking. The action of re-labelling with a revised measurement marking may also require the person to identify themselves as the packer. Hence, they would have to include their name and address on the package.

Repacking and topping up

- Identify those individual packages which have failed due to excessive deficiency and repack or top them up

- Apply the same procedure to packages with permissible deficiencies which are causing a failure of the average, in sufficient numbers to bring about a sample average that equals or exceeds the nominal marked measurement

- Re-check a sample of this revised batch of packages to ensure that it now complies with the marked measurement

- Consider other remedial actions if these procedures are uneconomic or impractical.

Selling non-compliant goods

Selling goods that don’t comply with package labelling laws can incur penalties. Where the breach is minor, however, NMI may issue a permit to sell these goods under certain conditions, including:

- breaches are not misleading

- rectifying the breach would impose unnecessary costs on the business.

See our Register of permits issued for more details.