Goal: Australian industries are supported to integrate robotics and automation technologies into their operations in ways that benefit Australian workers and communities.

What we’ve heard

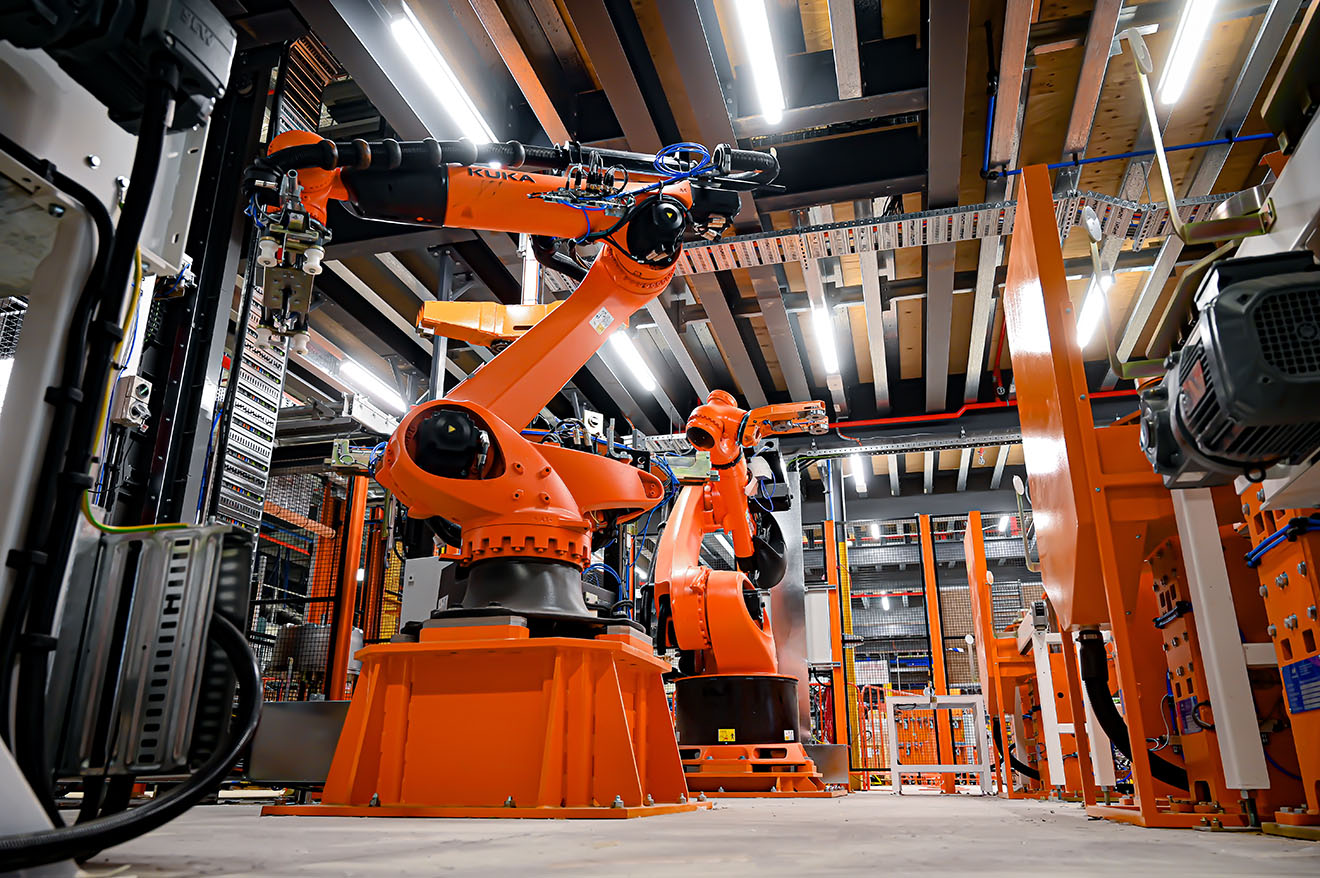

Robotics and automation technologies have far-reaching benefits. They will improve productivity and worker safety in many Australian industries, as well as create higher quality work for Australians. We are well positioned to increase the adoption of these technologies across the economy. Sectors that have high costs associated with upgrading business processes and infrastructure can learn from sectors who are already leading in the uptake of these technologies.

Australia is a leader in adopting whole-of-system automation solutions in mining and resources. These solutions have improved worker safety by removing risks in dangerous environments or the need to perform unsafe tasks. In other sectors, greater adoption could help address business problems by filling gaps in skills and labour, scaling production as well as improving sustainability. Stakeholders told us that companies adopting robotics have seen a range of benefits, including:

- increased labour productivity across industries

- increased scalability of production and manufacturing capability

- improved precision and reliability

- reduced operating costs

- reduced waste and environmental impact

- optimised resource management

- more employment opportunities due to increased scale of operations

- improved health and safety

- increased worker satisfaction.

Despite the benefits of robotics and automation, there are several barriers to adoption. Australian businesses need help to understand the advantages of robotics and automation. It can be difficult for organisations to find information on new technologies, including developments, trends, costs and installation time. Organisations need better visibility of how other Australian companies have adopted robotics and how this has improved their business.

There are also short-term costs and risks for companies looking to adopt robotics and automation solutions. Many businesses, particularly SMEs, are hesitant to adopt robotics because of a perceived high cost of entry. Existing business processes will need to change to realise the full benefits of adopting new technologies, and costs associated with upgrading infrastructure can be high. This often involves buying new stock, upgrading underpinning infrastructure, updating procedures and investing in training and work health and safety.

These barriers are compounded by Australian businesses often seeking international off-the-shelf solutions, rather than bespoke Australian solutions that may offer more localised support. Some businesses told us they chose international solutions because they were overwhelmed by the range of robotics and automation solutions available. Some businesses were also deterred by the perceived risks of working with a newer Australian robotics business. The availability and reliability of supporting infrastructure is also important for businesses looking to adopt these technologies. For instance, reliable internet connections and high upload speeds depend on digital infrastructure, which, if inadequate, can be a barrier to successful operations and growth.

For Australian industry, reliable access to strong, trusted domestic and international supply chains for essential materials and components is critical. Complex global supply chains can be vulnerable to disruption, resulting in unpredictable availability and costs for manufacturers. For example, industry has reported wait times of up to 36 months for some industrial robot arms. Without strong, secure and diverse supply chains, Australia faces barriers in maintaining, growing and diversifying our local manufacturing capabilities. These barriers will continue to result in businesses relying on overseas suppliers to import robotics technologies that we could supply ourselves.

Technological advances have helped address some of these barriers. Improvements made to robotics interfaces and usability, particularly in cobotics, have lowered technical barriers to adoption. Similarly, the use of digital twins – the virtual modelling of physical objects and environments – allows adopters to visualise how they can use robotics in their business by affordably simulating robotics in context.

Through increased adoption of robotics and automation, businesses can develop more productive business models, help build scale and access new markets for products. Sectors that are earlier adopters can also demonstrate to other businesses the potential use cases and commercial benefits from adopting trusted Australian solutions. These collaborative efforts can ultimately attract domestic and foreign investment for robot manufacturers and businesses who are adopting solutions, especially for manufacturers at the seed and startup stages.