Goal: Australia has a strong, collaborative robotics and automation ecosystem that is recognised for its strengths, has a thriving domestic market and exports globally.

What we’ve heard

Australia is internationally renowned for our strong technical expertise and innovations. Some of our inventions are well-known and widely celebrated, such as the cochlear implant, black box flight recorder, Wi-Fi and polymer banknotes. Others go underappreciated, including some of our major achievements in robotics and automation. For example, research performed by the Australian Centre for Field Robotics (ACFR) between 1995 and 2001 produced one of the most important advances in robotics in the past 2 decades. The papers published by members of the centre on the Simultaneous Localisation and Mapping (SLAM) method are among the most highly cited in robotics world-wide. The SLAM method allows a robot to build a map of its environment while it determines its location. This innovation is vital to technologies across the globe, such as autonomous vehicles, drones, robot vacuum cleaners and virtual reality headsets.

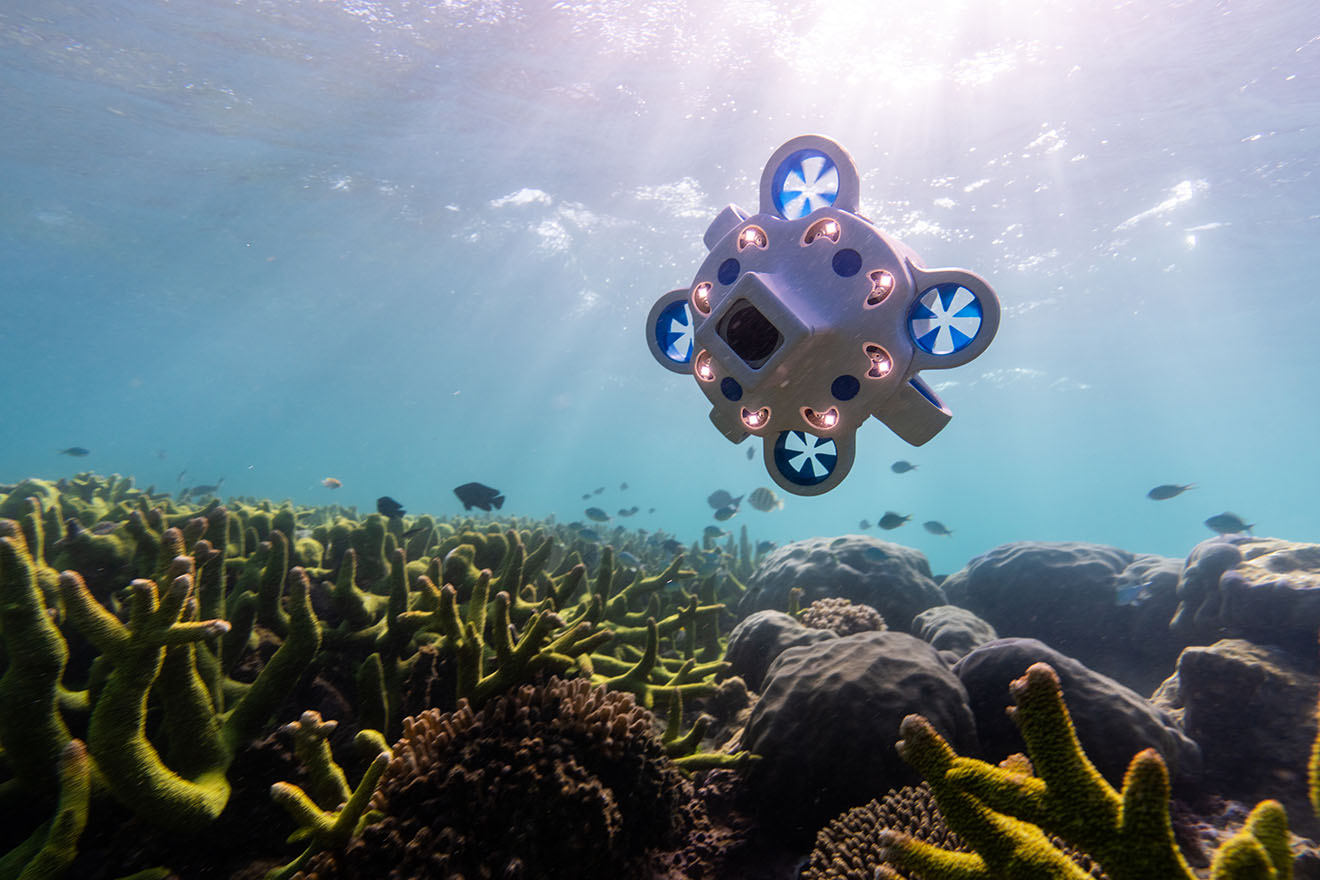

Australia has leading academic and government robotics institutions. They produce globally competitive research and innovation, with a strong focus on field and other service robots. This expertise is partly shaped by our geography – our vast and diverse landscape is ideal for testing and deploying large or remotely operated robots. Our R&D strengths and field robotics expertise are the foundation of our current robotics industry.

Australia has a competitive advantage in developing niche and high-quality robotic systems. We excel in integrating and customising robotics and automation solutions, particularly autonomous vehicles and drones for the mining, resources and defence sectors. Australia is increasingly commercialising solutions for medical sciences and agriculture, such as robots to support health research and drones for crop and livestock monitoring. Australia’s robotics industry also has strengths in:

- Supplying and customising hardware for robotic platforms. This involves adding bespoke features and capabilities to existing industrial robot systems.

- Providing integration services such as analysing business processes and optimising them through robotics and automation.

- Developing software and AI technologies for robots, including computer vision and sensing technologies.

By using our strengths and investing strategically, we can build a Future Made in Australia and grow an internationally competitive robotics and automation sector. However, Australia faces barriers in commercialising and scaling up our innovations. This is partly because of the limited availability of domestic and foreign capital where investors may see robotics as a risky investment. They can also be unwilling to fund technologies which have a longer expected return on investment.

Australia’s robotics and automation industry consists mostly of small companies, rather than end-to-end manufacturers of large-scale robotics solutions. These small companies tend to focus on niche areas of robotics and automation technologies or different points of the research-to-integration pipeline. Several of these companies are leading global exporters in their field.

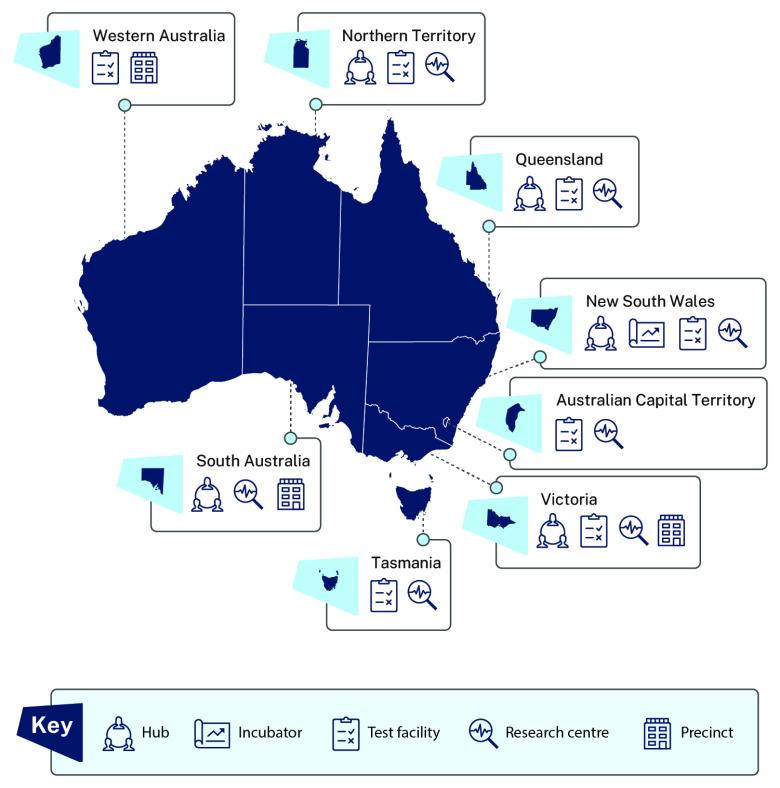

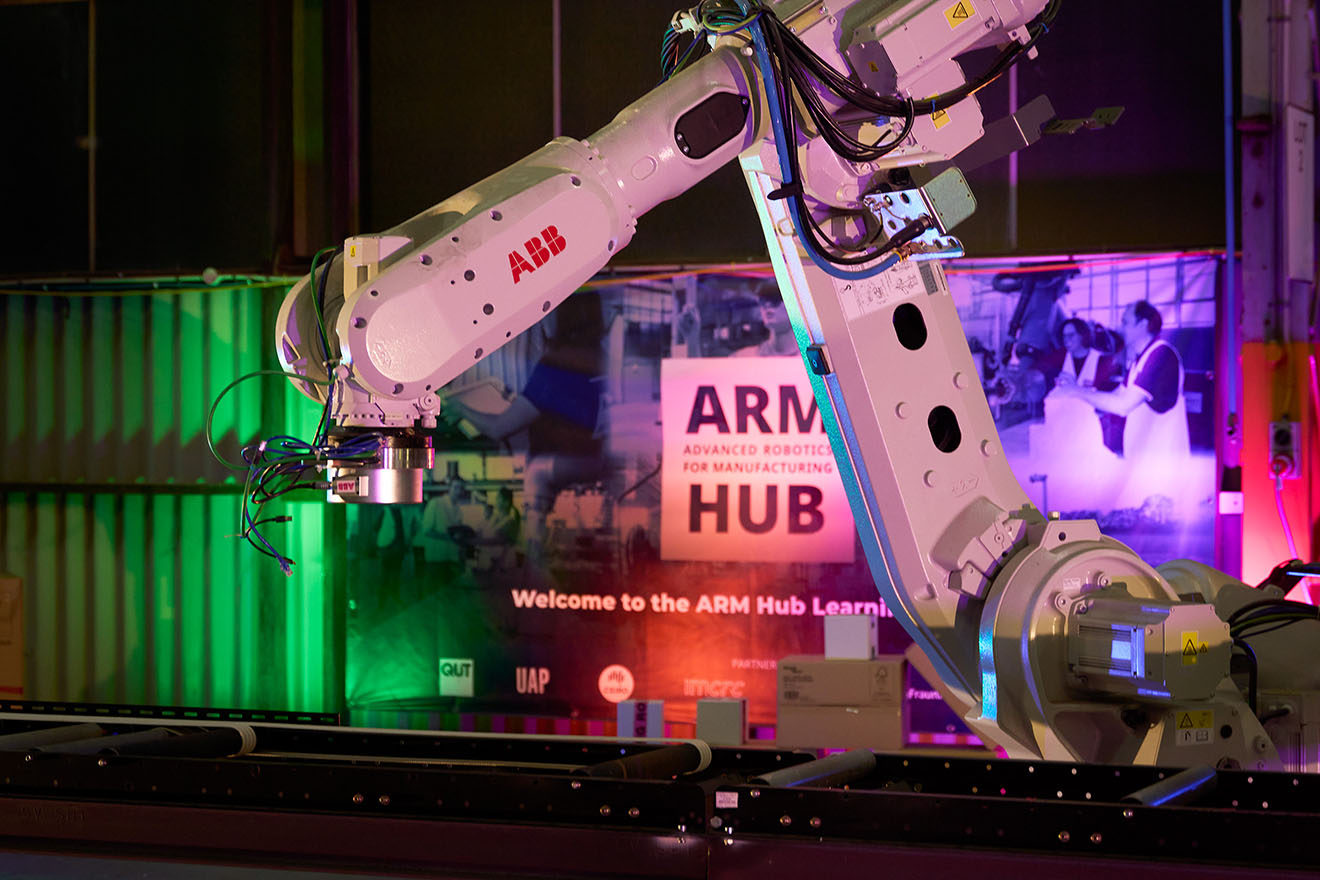

Australia is home to many robotics facilities that offer collaborative spaces with specialised equipment, expertise and resources. These spaces bring industry, researchers and government together to collaborate and help industry development. Robotics facilities are spread throughout the country and have developed strong expertise in their areas of focus. These spaces present opportunities to further scale, improve coordination, support collaboration and bring together Australia’s robotics industry.